10 月 . 09, 2024 01:35 Back to list

Innovative Smart Embroidery Machines for Modern Manufacturing Solutions in Factories

The Advancements of Smart Embroidery Machine Factories

In the realm of textile production, smart embroidery machine factories are revolutionizing the industry through automation and advanced technology. These modern facilities integrate sophisticated machinery with artificial intelligence, enabling a level of precision and efficiency that traditional factories cannot match. By harnessing the power of smart technology, manufacturers are redefining the crafting of embroidered textiles.

At the core of smart embroidery machine factories is the use of computer-controlled embroidery machines, which produce intricate designs with minimal human intervention. These machines are capable of executing complex patterns and designs at high speeds, drastically reducing production time while maintaining exceptional quality. The integration of AI algorithms allows for real-time adjustments during production, ensuring that the machines operate optimally and that any potential issues are addressed instantly.

Moreover, smart factories employ the Internet of Things (IoT) to connect different machines and processes. This connectivity facilitates the seamless exchange of data, allowing for comprehensive tracking of production metrics, such as efficiency, downtime, and output quality. With this data-driven approach, factory managers can make informed decisions, optimize workflows, and enhance overall operational efficiency. Predictive maintenance powered by AI also ensures that machines are serviced before any major malfunctions occur, thus minimizing potential disruptions in production.

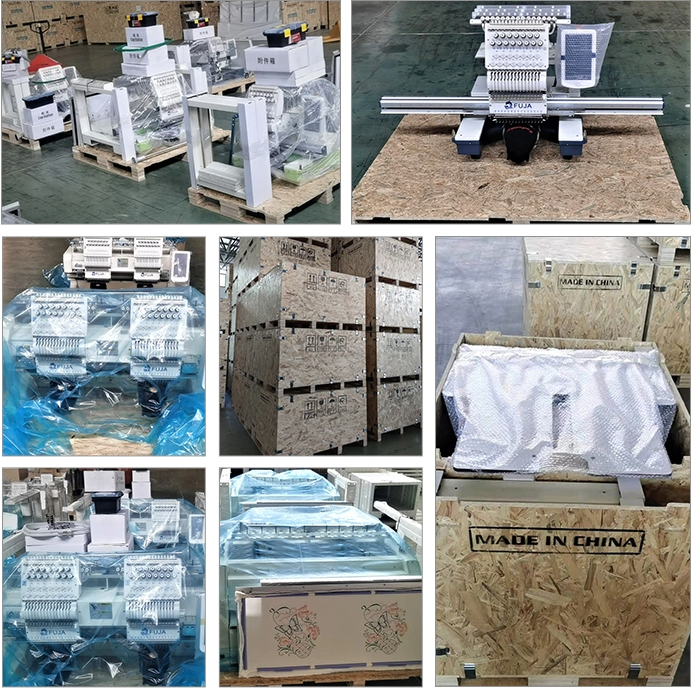

smart embroidery machine factories

Sustainability is another significant advantage of smart embroidery machine factories. These facilities utilize eco-friendly practices and materials, reducing waste and energy consumption. Advanced technology allows for precise calculations regarding fabric usage, minimizing leftover materials. This aligns with the growing demand for sustainable practices in the textile industry, as consumers increasingly prefer products that are environmentally conscious.

Additionally, smart embroidery factories can easily adapt to market trends. With customizable software solutions, they can quickly modify designs or production processes to meet the changing demands of consumers. This flexibility not only improves customer satisfaction but also allows businesses to maintain a competitive edge in a fast-paced market.

In conclusion, the emergence of smart embroidery machine factories marks a significant milestone in textile manufacturing. By leveraging automation, IoT, and AI, these facilities offer unprecedented efficiency, quality, and sustainability. As technology continues to evolve, it is likely that smart factories will become the standard in the embroidery industry, paving the way for a new era of production that meets the demands of modern consumers. The future of textile manufacturing looks remarkably bright, with smart factories leading the charge towards innovation and excellence.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy