6 月 . 12, 2024 10:36 Back to list

Smart embroidery machine factories offer efficient solutions.

Revolutionizing the Embroidery Industry A Look into Smart Embroidery Machine Factories

In the ever-evolving landscape of manufacturing, the advent of smart technology has significantly transformed various industries, including the world of embroidery. Smart embroidery machine factories are at the forefront of this revolution, leveraging cutting-edge innovations to enhance productivity, efficiency, and design quality in embroidery production.

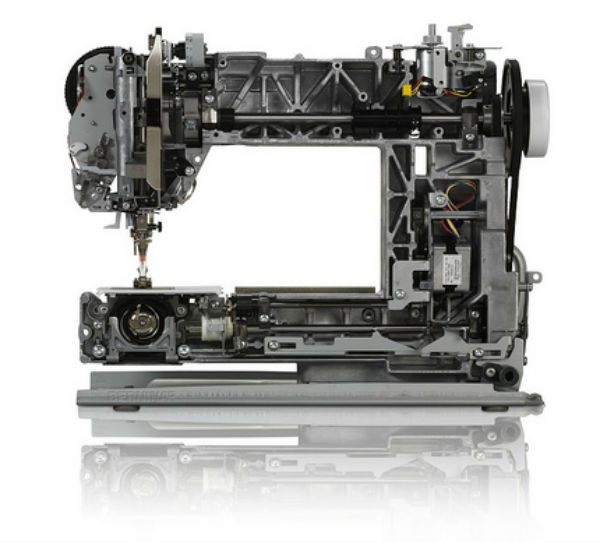

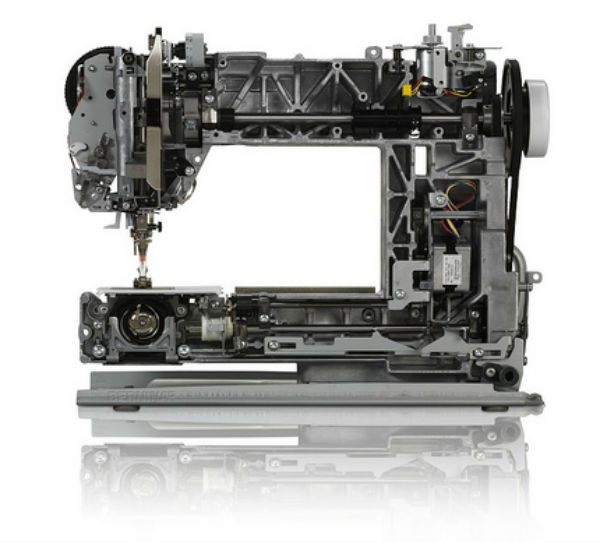

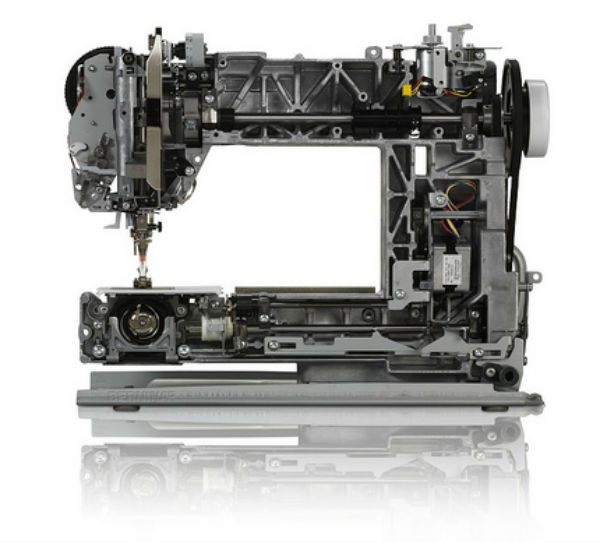

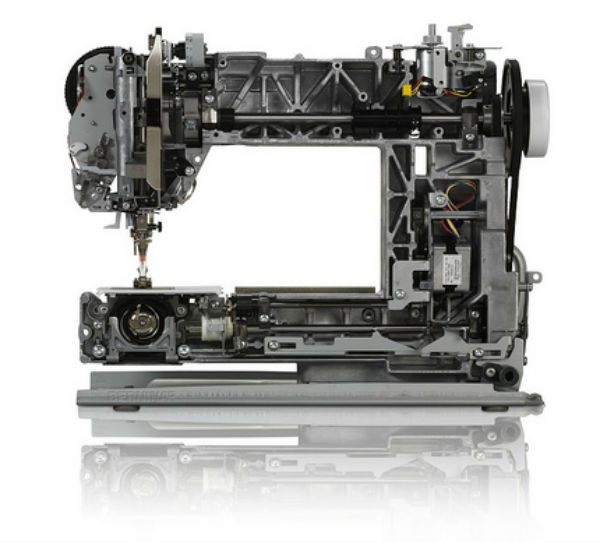

Smart embroidery machine factories are characterized by their integration of advanced computer systems, automated machinery, and sophisticated software that work in harmony to streamline the embroidery process. These facilities are equipped with machines that can interpret complex patterns with precision, ensuring consistent high-quality results across vast quantities of fabric. The machines are designed to detect and correct any imperfections autonomously, reducing waste and downtime significantly.

One of the key features of these smart factories is the use of predictive maintenance systems. These systems analyze data from the machines' sensors to predict when maintenance will be needed, preventing unexpected downtime and keeping the production line running smoothly. Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world

Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world smart embroidery machine factories.

Furthermore, smart embroidery machine factories have also embraced sustainable practices. They utilize energy-efficient lighting and machinery, reduce water consumption through recycling systems, and implement waste management strategies that minimize environmental impact. This commitment to sustainability not only benefits the planet but also appeals to a customer base increasingly conscious of eco-friendly practices.

The shift towards smart embroidery machine factories represents a significant milestone in the evolution of the embroidery industry. By harnessing the power of intelligent technology and automation, these facilities are setting new standards for efficiency, quality, and sustainability. As we move forward, it is exciting to envision the endless possibilities that smart technology will continue to unlock in transforming traditional crafts into modern marvels of production.

smart embroidery machine factories.

Furthermore, smart embroidery machine factories have also embraced sustainable practices. They utilize energy-efficient lighting and machinery, reduce water consumption through recycling systems, and implement waste management strategies that minimize environmental impact. This commitment to sustainability not only benefits the planet but also appeals to a customer base increasingly conscious of eco-friendly practices.

The shift towards smart embroidery machine factories represents a significant milestone in the evolution of the embroidery industry. By harnessing the power of intelligent technology and automation, these facilities are setting new standards for efficiency, quality, and sustainability. As we move forward, it is exciting to envision the endless possibilities that smart technology will continue to unlock in transforming traditional crafts into modern marvels of production.

Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world

Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world Additionally, the implementation of Internet of Things (IoT) technology allows for real-time monitoring and control of the entire production process remotely, making it possible to adjust parameters and troubleshoot from anywhere in the world smart embroidery machine factories.

Furthermore, smart embroidery machine factories have also embraced sustainable practices. They utilize energy-efficient lighting and machinery, reduce water consumption through recycling systems, and implement waste management strategies that minimize environmental impact. This commitment to sustainability not only benefits the planet but also appeals to a customer base increasingly conscious of eco-friendly practices.

The shift towards smart embroidery machine factories represents a significant milestone in the evolution of the embroidery industry. By harnessing the power of intelligent technology and automation, these facilities are setting new standards for efficiency, quality, and sustainability. As we move forward, it is exciting to envision the endless possibilities that smart technology will continue to unlock in transforming traditional crafts into modern marvels of production.

smart embroidery machine factories.

Furthermore, smart embroidery machine factories have also embraced sustainable practices. They utilize energy-efficient lighting and machinery, reduce water consumption through recycling systems, and implement waste management strategies that minimize environmental impact. This commitment to sustainability not only benefits the planet but also appeals to a customer base increasingly conscious of eco-friendly practices.

The shift towards smart embroidery machine factories represents a significant milestone in the evolution of the embroidery industry. By harnessing the power of intelligent technology and automation, these facilities are setting new standards for efficiency, quality, and sustainability. As we move forward, it is exciting to envision the endless possibilities that smart technology will continue to unlock in transforming traditional crafts into modern marvels of production. Latest news

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy