7 月 . 30, 2024 04:50 Back to list

Innovative Multi-Head Machine Embroidery Solutions for Your Custom Design Needs

The Rise of Multi-Head Machine Embroidery Factories Transforming the Textile Industry

In recent years, the textile industry has witnessed a significant transformation, thanks in large part to advancements in technology. Among these innovations, multi-head machine embroidery has emerged as a game changer. Factories specializing in multi-head embroidery machines are revolutionizing the way embroidery is produced, integrating speed, efficiency, and creativity to meet the growing demands of the market.

Multi-head embroidery machines are designed to operate multiple needles simultaneously, allowing for the production of numerous embroidered items in one go. This capability not only enhances productivity but also ensures uniformity and precision across all items produced. Unlike traditional embroidery methods, which often rely on single-needle machines and require more manual intervention, multi-head systems automate much of the process. As a result, factories can significantly reduce labor costs while simultaneously increasing output.

The Rise of Multi-Head Machine Embroidery Factories Transforming the Textile Industry

Additionally, these factories possess the capacity to customize designs on a massive scale. Whether it’s a logo for a corporate event, personalized gifts, or intricate custom designs for fashion collections, multi-head embroidery machines can produce high-quality results with intricate details. Advanced software allows designers to create complex patterns that can be easily executed by the machine. This not only saves time but also pushes the creative boundaries of what is possible in textile decoration.

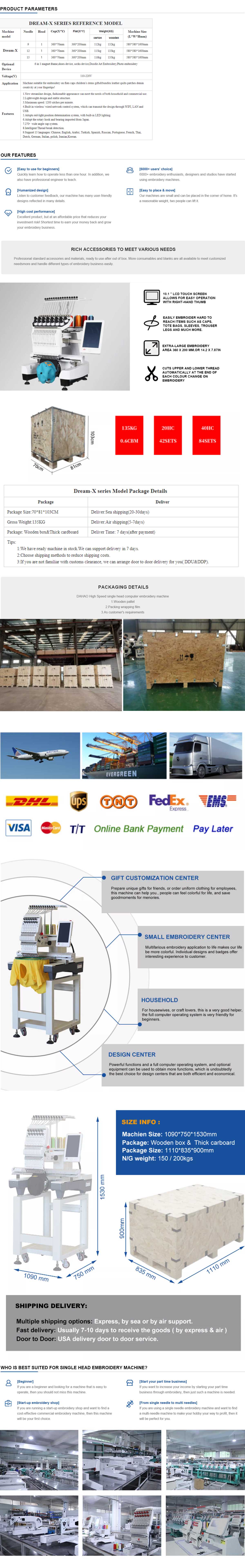

multi head machine embroidery factory

Furthermore, sustainability is becoming increasingly important in the textile industry, and multi-head embroidery factories are well-positioned to contribute positively in this regard. The efficiency of these machines means they consume less energy and generate less waste compared to conventional methods. Additionally, advancements in thread technology and fabric sourcing are enabling factories to use eco-friendly materials, reducing their overall environmental footprint. The capacity to produce high-quality goods efficiently aligns with the growing demand for sustainable practices in manufacturing.

Despite the undeniable benefits, there are challenges associated with the transition to multi-head machine embroidery. The initial investment in machinery can be substantial, deterring small businesses from upgrading. Additionally, maintaining and operating these sophisticated machines requires skilled personnel who are familiar with both the technical and creative aspects of embroidery. Therefore, training and workforce development become crucial components for the success of a multi-head machine embroidery factory.

As we look to the future, the impact of multi-head machine embroidery factories on the textile industry is poised to deepen. With ongoing advancements in technology, including improvements in automation and artificial intelligence, these factories will continue to evolve, pushing the envelope of efficiency and creativity. They are not just a trend but represent a fundamental shift in how we approach design and production in the textile sector.

In conclusion, the emergence of multi-head machine embroidery factories marks a pivotal moment in the textile industry. By combining innovative technology with skilled craftsmanship, these facilities enhance productivity and creativity, catering to the modern demand for customized and sustainable products. As they continue to grow, their influence will shape the future of embroidery, revolutionizing the way textiles are adorned and celebrated.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy