1 月 . 17, 2025 00:56 Back to list

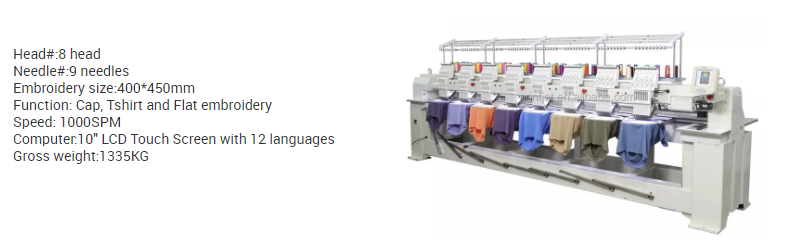

industrial embroidery machine

Industrial embroidery machines have revolutionized the textile industry, offering unparalleled efficiency, precision, and productivity. As a seasoned expert in embroidery machine technology, I have had the privilege of working with various models and brands, each contributing to a deeper understanding of what truly makes a machine extraordinary. Over the years, I’ve garnered insights that could be invaluable for businesses considering the leap into industrial embroidery.

The market for industrial embroidery machines is replete with options, but expertise guides us toward understanding that not all are created equal. Features such as multi-head functionality, speed settings, and hoop choices significantly impact functionality and should align with the business’s production needs. Machines that offer flexible hoop configurations enable businesses to cater to a wider array of products, thus broadening their market reach. Another critical consideration is the cost versus benefit analysis in acquiring industrial embroidery machines. The initial investment is steep, yet the accurate assessment of increased production capability and product quality can provide significant returns. High-volume operations often find that the throughput and precision justify the expense, and the investment pays for itself over time. Trustworthiness in supplier relationships also plays a role; reputable suppliers often provide not only sales but also post-sale support and machine servicing. In conclusion, delving into the realm of industrial embroidery machines requires careful consideration and due diligence. From the technological marvel of automation to the economic benefits of scaling production, the machinery serves as an invaluable asset to textile businesses. Harnessing the potential of these machines involves not just understanding the mechanics but also leveraging expertise in design software and maintenance. Companies that align their operations with these advanced technologies position themselves as formidable contenders in the textile industry, ready to meet evolving consumer demands with efficiency and creativity.

The market for industrial embroidery machines is replete with options, but expertise guides us toward understanding that not all are created equal. Features such as multi-head functionality, speed settings, and hoop choices significantly impact functionality and should align with the business’s production needs. Machines that offer flexible hoop configurations enable businesses to cater to a wider array of products, thus broadening their market reach. Another critical consideration is the cost versus benefit analysis in acquiring industrial embroidery machines. The initial investment is steep, yet the accurate assessment of increased production capability and product quality can provide significant returns. High-volume operations often find that the throughput and precision justify the expense, and the investment pays for itself over time. Trustworthiness in supplier relationships also plays a role; reputable suppliers often provide not only sales but also post-sale support and machine servicing. In conclusion, delving into the realm of industrial embroidery machines requires careful consideration and due diligence. From the technological marvel of automation to the economic benefits of scaling production, the machinery serves as an invaluable asset to textile businesses. Harnessing the potential of these machines involves not just understanding the mechanics but also leveraging expertise in design software and maintenance. Companies that align their operations with these advanced technologies position themselves as formidable contenders in the textile industry, ready to meet evolving consumer demands with efficiency and creativity.

Latest news

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy