10 月 . 16, 2024 15:48 Back to list

embroidery machine small factories

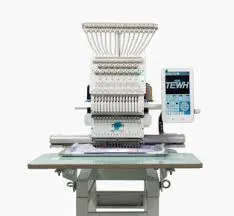

The Rise of Small Factories in the Embroidery Machine Industry

In recent years, the embroidery machine industry has experienced a significant transformation, particularly with the rise of small factories that specialize in the production of these intricate and versatile machines

. As the demand for customized and high-quality embroidery has surged across various sectors, from fashion to home decor, small factories have emerged as vital players in this dynamic market.Small factories, often characterized by their flexibility and ability to adapt quickly to market trends, have become increasingly popular among entrepreneurs and established businesses alike. Unlike large manufacturing plants, these smaller operations can efficiently manage production runs of varying sizes, catering to both bulk orders and specialized requests. This adaptability is essential in a market where consumer preferences are constantly changing and personalization is key.

One of the main advantages of small embroidery machine factories is their capacity to innovate. Many of these factories are equipped with the latest technologies that allow them to produce advanced embroidery machines capable of intricate designs and high-speed production. With a focus on quality, these factories often employ skilled craftsmen who are adept at operating sophisticated machinery, ensuring that each machine meets rigorous standards of performance and reliability.

Moreover, small factories can foster closer relationships with their clients. Unlike larger manufacturers, where communication can be impersonal and bureaucratic, small factories often prioritize customer service and collaboration. This enables them to better understand the specific needs of their clients, whether they are small businesses looking to scale up their production or individual entrepreneurs seeking customizable solutions for their embroidery projects.

embroidery machine small factories

The rise of e-commerce has also played a significant role in the growth of small embroidery machine factories. With the ability to market their products online, these factories can reach a broader audience, breaking free from geographical constraints that previously limited their customer base. Social media platforms and dedicated websites allow them to showcase their offerings and connect directly with potential buyers, enhancing visibility and driving sales.

In addition to these advantages, small factories often emphasize sustainability practices, appealing to environmentally conscious consumers. By adopting eco-friendly materials and efficient production methods, these businesses not only reduce their carbon footprint but also attract a growing segment of the market that values ethical and sustainable manufacturing processes.

However, the journey for small embroidery machine factories is not without challenges. Competition from larger manufacturers, who benefit from economies of scale, can make it difficult for smaller operations to maintain competitive pricing. Additionally, access to advanced technology and skilled labor can be a hurdle for some small manufacturers, requiring ongoing investment in training and equipment.

Despite these challenges, the growth potential in the market remains robust. As the demand for customized and unique embroidery continues to rise, small factories are well-positioned to capitalize on emerging trends. By focusing on innovation, quality, and customer service, they can carve out a niche for themselves in a landscape dominated by larger manufacturers.

In conclusion, the small factory model in the embroidery machine industry reflects the broader trends of personalization, flexibility, and sustainability that are shaping the global market today. As these small businesses continue to innovate and adapt, they will play an increasingly important role in meeting the diverse needs of consumers and businesses, driving the future of embroidery machinery in exciting new directions.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy