6 月 . 12, 2024 13:32 Back to list

Embroidery machine repair and maintenance for businesses

The Pivotal Role of Service in the World of Commercial Embroidery Machines

In the realm of textile artistry and manufacturing, commercial embroidery machines have revolutionized the way designs are intricately woven into fabrics. These advanced machines, with their precision and speed, have transformed embroidery from a time-consuming craft to a high-volume, efficient process. However, behind every stitch and thread, lies an essential element that ensures seamless operation - the service and maintenance of these machines.

Commercial embroidery machines, like any other industrial equipment, require regular care and attention to maintain optimal performance. A well-serviced machine not only guarantees consistent quality output but also extends its lifespan, reducing the need for frequent replacements and minimizing downtime. The importance of this service cannot be overstated, as it directly impacts the productivity and profitability of businesses relying on embroidery services.

Service encompasses a range of activities, starting from routine cleaning to more complex repairs and upgrades. Regular cleaning removes accumulated dust and debris that can hinder the machine's performance. Lubrication of moving parts is crucial to prevent friction and wear, ensuring smooth operation. Moreover, regular inspections by skilled technicians can identify potential issues before they escalate into major problems.

The software aspect of these machines also requires timely updates and maintenance. As technology advances, new embroidery designs and features become available, necessitating software upgrades to stay competitive. These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands

These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands commercial embroidery machines service.

Moreover, a comprehensive service contract provides peace of mind. It typically includes prompt repairs, emergency assistance, and preventive maintenance, all critical for businesses that rely on uninterrupted production. A reliable service provider should offer timely response times, experienced technicians, and genuine spare parts to ensure minimal disruption.

Furthermore, training on machine operation and maintenance is another vital service component. Operators need to understand the intricacies of the machine to avoid misuse, while maintenance personnel require specialized knowledge to handle repairs effectively. This training not only optimizes machine performance but also fosters a culture of responsibility and care within the workforce.

In conclusion, the service aspect of commercial embroidery machines is a strategic investment that safeguards the overall functionality, efficiency, and longevity of these machines. It is a testament to the adage, Prevention is better than cure. By prioritizing regular maintenance and timely service, businesses can harness the full potential of their embroidery machines, delivering top-quality products while maintaining operational efficiency. In the dynamic world of embroidery, a well-serviced machine is indeed a powerful tool driving success.

commercial embroidery machines service.

Moreover, a comprehensive service contract provides peace of mind. It typically includes prompt repairs, emergency assistance, and preventive maintenance, all critical for businesses that rely on uninterrupted production. A reliable service provider should offer timely response times, experienced technicians, and genuine spare parts to ensure minimal disruption.

Furthermore, training on machine operation and maintenance is another vital service component. Operators need to understand the intricacies of the machine to avoid misuse, while maintenance personnel require specialized knowledge to handle repairs effectively. This training not only optimizes machine performance but also fosters a culture of responsibility and care within the workforce.

In conclusion, the service aspect of commercial embroidery machines is a strategic investment that safeguards the overall functionality, efficiency, and longevity of these machines. It is a testament to the adage, Prevention is better than cure. By prioritizing regular maintenance and timely service, businesses can harness the full potential of their embroidery machines, delivering top-quality products while maintaining operational efficiency. In the dynamic world of embroidery, a well-serviced machine is indeed a powerful tool driving success.

These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands

These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands These updates often improve the machine's efficiency and expand its capabilities, allowing businesses to cater to diverse client demands commercial embroidery machines service.

Moreover, a comprehensive service contract provides peace of mind. It typically includes prompt repairs, emergency assistance, and preventive maintenance, all critical for businesses that rely on uninterrupted production. A reliable service provider should offer timely response times, experienced technicians, and genuine spare parts to ensure minimal disruption.

Furthermore, training on machine operation and maintenance is another vital service component. Operators need to understand the intricacies of the machine to avoid misuse, while maintenance personnel require specialized knowledge to handle repairs effectively. This training not only optimizes machine performance but also fosters a culture of responsibility and care within the workforce.

In conclusion, the service aspect of commercial embroidery machines is a strategic investment that safeguards the overall functionality, efficiency, and longevity of these machines. It is a testament to the adage, Prevention is better than cure. By prioritizing regular maintenance and timely service, businesses can harness the full potential of their embroidery machines, delivering top-quality products while maintaining operational efficiency. In the dynamic world of embroidery, a well-serviced machine is indeed a powerful tool driving success.

commercial embroidery machines service.

Moreover, a comprehensive service contract provides peace of mind. It typically includes prompt repairs, emergency assistance, and preventive maintenance, all critical for businesses that rely on uninterrupted production. A reliable service provider should offer timely response times, experienced technicians, and genuine spare parts to ensure minimal disruption.

Furthermore, training on machine operation and maintenance is another vital service component. Operators need to understand the intricacies of the machine to avoid misuse, while maintenance personnel require specialized knowledge to handle repairs effectively. This training not only optimizes machine performance but also fosters a culture of responsibility and care within the workforce.

In conclusion, the service aspect of commercial embroidery machines is a strategic investment that safeguards the overall functionality, efficiency, and longevity of these machines. It is a testament to the adage, Prevention is better than cure. By prioritizing regular maintenance and timely service, businesses can harness the full potential of their embroidery machines, delivering top-quality products while maintaining operational efficiency. In the dynamic world of embroidery, a well-serviced machine is indeed a powerful tool driving success. Latest news

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

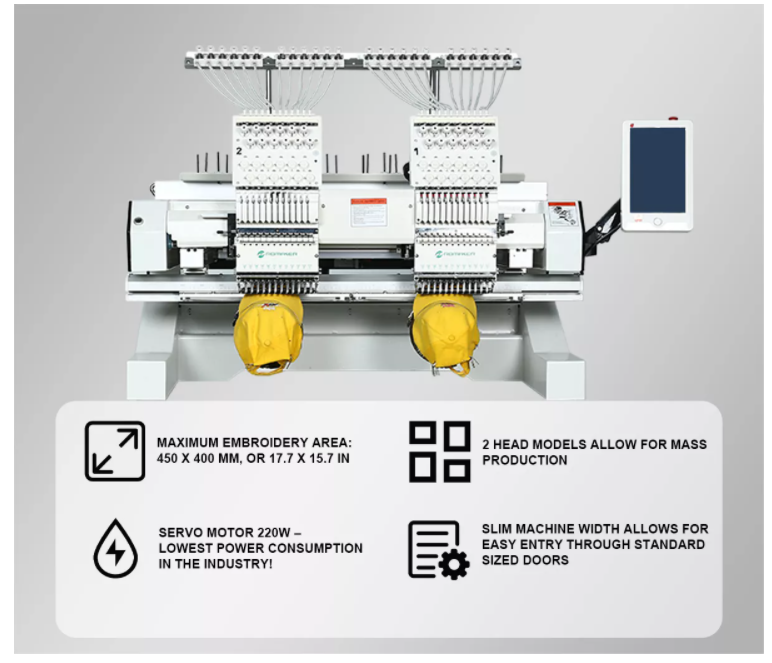

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy