8 月 . 28, 2024 06:57 Back to list

High-Quality Embroidery Machine Caps Factory | Custom Caps & Hats

The Evolution and Significance of Embroidery Machine Caps Factories

In recent years, the embroidery machine caps factory has emerged as an essential component of the textile industry. With the rise of customized fashion and promotional merchandise, the demand for high-quality embroidered caps has surged dramatically. These factories play a pivotal role in meeting the needs of both individual consumers and businesses.

The Process of Cap Embroidery

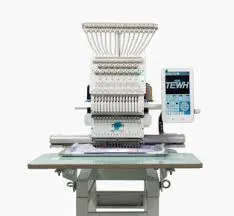

At the heart of an embroidery machine caps factory lies a sophisticated process that merges technology and artistry. The journey begins with design creation. Skilled designers utilize advanced software to create intricate patterns and logos that will be embroidered onto caps. Once the design is finalized, it is transferred to high-speed embroidery machines. These machines are equipped with multiple needles and can produce detailed designs with remarkable precision.

The choice of materials is also crucial. High-quality fabrics such as cotton, polyester, and blends are often selected to ensure durability and comfort. The embroidery process involves stitching the design onto the cap using colorful threads that enhance the visual appeal. Factories often employ a variety of embroidery techniques, including flat and 3D puff embroidery, allowing for versatility in the final product.

Customization and Market Demand

Customization is a key trend driving the success of embroidery machine caps factories. Businesses looking to enhance their brand visibility turn to these factories for tailored solutions. Embroidered caps serve as excellent promotional items, allowing companies to showcase their logos at events, trade shows, or through employee uniforms. In addition, individuals are increasingly seeking personalized caps for events like weddings, birthdays, and family reunions, leading to a boom in orders.

embroidery machine caps factory

The rise of e-commerce has further fueled the demand for embroidered caps. Online platforms enable consumers to design their caps from the comfort of their homes, choosing styles, colors, and embroidery designs. This convenience has opened up new markets for embroidery machine caps factories, allowing them to reach a broader audience.

Sustainability in the Industry

As the textile industry faces increasing scrutiny regarding environmental impact, embroidery machine caps factories are also exploring sustainable practices. Many are adopting eco-friendly materials and processes, such as using organic cotton or recycled fabrics. Additionally, energy-efficient machines and waste reduction techniques are becoming more common, aligning with the growing consumer demand for sustainable products.

Future Trends

Looking ahead, the embroidery machine caps factory sector is poised for significant growth. Innovations in automation and technology will streamline production processes, making them more efficient while maintaining high quality. Furthermore, the integration of artificial intelligence in design and manufacturing is expected to enhance customization capabilities, allowing for even more personalized products.

In conclusion, the embroidery machine caps factory is a dynamic and evolving part of the textile industry that combines traditional craftsmanship with modern technology. Its ability to meet the changing demands of consumers and businesses alike makes it a vital player in the market, with a promising future ahead. As the world moves towards more personalized and sustainable products, these factories will continue to innovate and adapt, reinforcing their importance in the global economy.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy