9 月 . 02, 2024 15:00 Back to list

High-Quality 12 Head Embroidery Machines – Factory Direct Supply

Exploring the World of 12-Head Embroidery Machines A Journey Through Factories

In the ever-evolving realm of textile production, the embroidery machine plays a pivotal role, particularly the sophisticated 12-head embroidery machine. These machines not only enhance productivity but also offer unrivaled precision and versatility for businesses. As we delve into this fascinating world, it’s essential to understand the intricate workings and the factories behind these technological marvels.

Exploring the World of 12-Head Embroidery Machines A Journey Through Factories

The manufacturing process of these machines involves several meticulous steps. High-quality materials, such as durable metals and state-of-the-art electronic components, are sourced to ensure longevity and reliability. Skilled technicians and engineers work collaboratively in well-equipped factories, applying precision engineering practices to assemble each part. This attention to detail guarantees that each machine is capable of delivering exceptional performance, even in the most demanding environments.

embroidery machine 12 head factory

Moreover, quality assurance plays a vital role in the production of 12-head embroidery machines. Factories implement rigorous testing procedures to evaluate the machines under various conditions, ensuring they meet international standards. This commitment to quality aligns with the growing need for reliable equipment in the embroidery market, allowing businesses to produce high-end products with confidence.

The versatility offered by 12-head machines is one of their standout features. They can handle a wide variety of fabrics, including cotton, polyester, and mixed materials. This adaptability enables businesses to cater to diverse markets—from fashion and apparel to home textiles and promotional goods. Consequently, factories producing these machines are essential partners for companies seeking to boost their output and maintain high-quality standards.

As the demand for customized goods continues to rise, the role of 12-head embroidery machines becomes increasingly significant. The factories dedicated to their production are not merely manufacturing hubs; they are innovation centers driving the future of embroidery technology. With advancements in artificial intelligence and automation on the horizon, the next generation of these machines promises even greater efficiency and creativity, solidifying their place as an indispensable tool in the textile industry.

In conclusion, the 12-head embroidery machine embodies the fusion of technology, precision, and creativity, empowering manufacturers to transform their ideas into reality. Understanding the factories behind these machines offers a glimpse into the rigorous processes that uphold their quality and reliability, ultimately shaping the landscape of modern embroidery.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

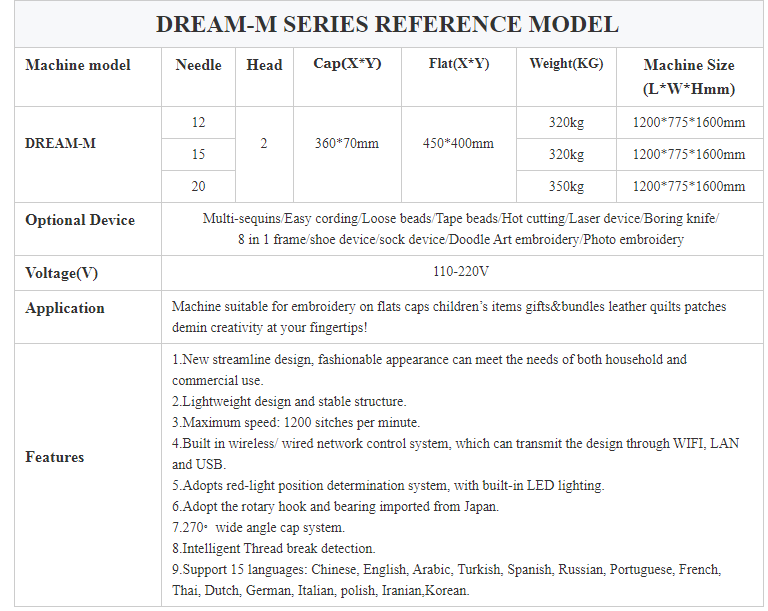

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy