6 月 . 19, 2024 05:38 Back to list

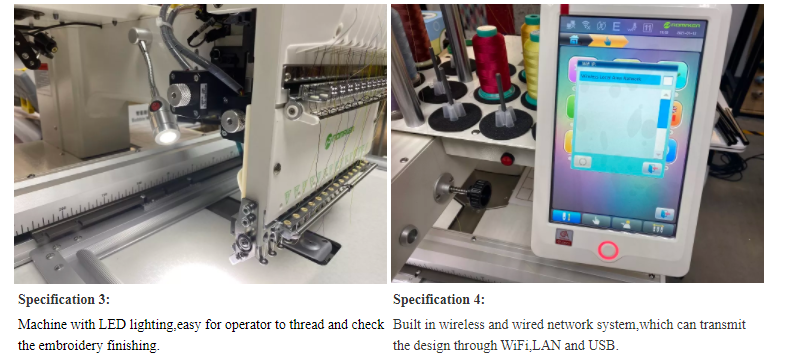

Computerized embroidery machine manufacturers

The Revolution of Embroidery Computerized Machine Factories

In the realm of textile artistry, embroidery has long been a symbol of craftsmanship and cultural expression. However, with the advent of computerized embroidery machines, this traditional art form has taken a technological leap, transforming the industry landscape in factories across the globe.

Computerized embroidery machine factories have revolutionized the process of embroidery, turning it from a time-consuming, artisanal endeavor into a highly efficient and precise manufacturing operation. These modern factories, equipped with state-of-the-art machinery, have reshaped the way embroidery is produced, increasing productivity and reducing costs significantly.

The heart of these factories lies in their sophisticated computerized embroidery machines. These machines, controlled by advanced software programs, can replicate intricate designs with remarkable accuracy and speed. The design process starts with a digital file, which could be an artist's sketch or a scanned image. This digital pattern is then fed into the machine, guiding the needle and thread to create the desired embroidery.

The precision offered by these machines is unparalleled. They can work with minute details, replicating complex patterns and logos with ease. Moreover, they can handle multiple threads simultaneously, producing multi-colored designs in a fraction of the time it would take by hand. This not only boosts efficiency but also enables mass production, catering to large-scale orders from various industries such as fashion, sports apparel, home textiles, and promotional merchandise.

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor embroidery computerized machine factories. While the machines automate the stitching process, skilled operators are still required to set up the machines, monitor the process, and troubleshoot any issues. They also play a crucial role in quality control, ensuring that each piece meets the high standards of the industry.

Moreover, these factories often adopt sustainable practices, minimizing waste and optimizing energy usage. Advanced embroidery machines have features like automatic thread trimming, reducing excess waste, while their energy-efficient design reduces carbon footprint.

Despite the automation, the essence of embroidery remains intact. The artistry and creativity are still at the core, now guided by technology. In fact, computerized embroidery machines have opened new avenues for creativity, allowing designers to explore more complex and innovative designs.

In conclusion, computerized embroidery machine factories have not only streamlined the embroidery industry but also elevated it to new heights. They embody the perfect blend of traditional artistry and modern technology, preserving the rich heritage of embroidery while embracing the future. As we continue to advance technologically, it will be fascinating to see how these factories evolve, further refining the art of embroidery.

embroidery computerized machine factories. While the machines automate the stitching process, skilled operators are still required to set up the machines, monitor the process, and troubleshoot any issues. They also play a crucial role in quality control, ensuring that each piece meets the high standards of the industry.

Moreover, these factories often adopt sustainable practices, minimizing waste and optimizing energy usage. Advanced embroidery machines have features like automatic thread trimming, reducing excess waste, while their energy-efficient design reduces carbon footprint.

Despite the automation, the essence of embroidery remains intact. The artistry and creativity are still at the core, now guided by technology. In fact, computerized embroidery machines have opened new avenues for creativity, allowing designers to explore more complex and innovative designs.

In conclusion, computerized embroidery machine factories have not only streamlined the embroidery industry but also elevated it to new heights. They embody the perfect blend of traditional artistry and modern technology, preserving the rich heritage of embroidery while embracing the future. As we continue to advance technologically, it will be fascinating to see how these factories evolve, further refining the art of embroidery.

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor

However, the transition to computerized embroidery hasn't negated the need for skilled labor embroidery computerized machine factories. While the machines automate the stitching process, skilled operators are still required to set up the machines, monitor the process, and troubleshoot any issues. They also play a crucial role in quality control, ensuring that each piece meets the high standards of the industry.

Moreover, these factories often adopt sustainable practices, minimizing waste and optimizing energy usage. Advanced embroidery machines have features like automatic thread trimming, reducing excess waste, while their energy-efficient design reduces carbon footprint.

Despite the automation, the essence of embroidery remains intact. The artistry and creativity are still at the core, now guided by technology. In fact, computerized embroidery machines have opened new avenues for creativity, allowing designers to explore more complex and innovative designs.

In conclusion, computerized embroidery machine factories have not only streamlined the embroidery industry but also elevated it to new heights. They embody the perfect blend of traditional artistry and modern technology, preserving the rich heritage of embroidery while embracing the future. As we continue to advance technologically, it will be fascinating to see how these factories evolve, further refining the art of embroidery.

embroidery computerized machine factories. While the machines automate the stitching process, skilled operators are still required to set up the machines, monitor the process, and troubleshoot any issues. They also play a crucial role in quality control, ensuring that each piece meets the high standards of the industry.

Moreover, these factories often adopt sustainable practices, minimizing waste and optimizing energy usage. Advanced embroidery machines have features like automatic thread trimming, reducing excess waste, while their energy-efficient design reduces carbon footprint.

Despite the automation, the essence of embroidery remains intact. The artistry and creativity are still at the core, now guided by technology. In fact, computerized embroidery machines have opened new avenues for creativity, allowing designers to explore more complex and innovative designs.

In conclusion, computerized embroidery machine factories have not only streamlined the embroidery industry but also elevated it to new heights. They embody the perfect blend of traditional artistry and modern technology, preserving the rich heritage of embroidery while embracing the future. As we continue to advance technologically, it will be fascinating to see how these factories evolve, further refining the art of embroidery. Latest news

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy