1 月 . 17, 2025 03:30 Back to list

6 needle embroidery machine

The allure of embroidery has transcended centuries, evolving from a handcraft passed down through generations to becoming an integral component of modern textile production. Among the myriad embroidery machines available today, the 6 needle embroidery machine stands out as a versatile tool that bridges the gap between hobbyists and professional embroiderers. Understanding the nuances of this machine can significantly enhance both the quality of the craftsmanship and the efficiency of workflow in textile projects.

Another aspect that contributes to the machine's popularity is its durability and low maintenance requirements. Built with industrial-grade components, these machines are designed to withstand extensive use without compromising performance. Regular maintenance primarily involves simple cleaning and occasional lubrication, ensuring the machine runs smoothly with minimal interruptions. The credibility of the 6 needle embroidery machine is further reinforced by endorsements from industry experts and positive user testimonials. Many professional crafters and embroidery businesses attest to the machine's reliability and precision, frequently citing how it has transformed their processes and increased output quality. Such endorsements not only highlight the machine's technical capabilities but also build trust with potential buyers who are considering an investment in embroidery technology. In summary, the 6 needle embroidery machine represents a convergence of art and technology, offering users an efficient way to bring intricate and colorful designs to life. Its innovative features, such as multi-color threading, automated processes, and user-friendly interfaces, underscore its value in both personal and professional settings. As more artisans and businesses seek tools that enhance creativity while optimizing efficiency, the 6 needle embroidery machine remains a standout choice, appreciated for its blend of traditional artistry and modern engineering.

Another aspect that contributes to the machine's popularity is its durability and low maintenance requirements. Built with industrial-grade components, these machines are designed to withstand extensive use without compromising performance. Regular maintenance primarily involves simple cleaning and occasional lubrication, ensuring the machine runs smoothly with minimal interruptions. The credibility of the 6 needle embroidery machine is further reinforced by endorsements from industry experts and positive user testimonials. Many professional crafters and embroidery businesses attest to the machine's reliability and precision, frequently citing how it has transformed their processes and increased output quality. Such endorsements not only highlight the machine's technical capabilities but also build trust with potential buyers who are considering an investment in embroidery technology. In summary, the 6 needle embroidery machine represents a convergence of art and technology, offering users an efficient way to bring intricate and colorful designs to life. Its innovative features, such as multi-color threading, automated processes, and user-friendly interfaces, underscore its value in both personal and professional settings. As more artisans and businesses seek tools that enhance creativity while optimizing efficiency, the 6 needle embroidery machine remains a standout choice, appreciated for its blend of traditional artistry and modern engineering.

Latest news

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

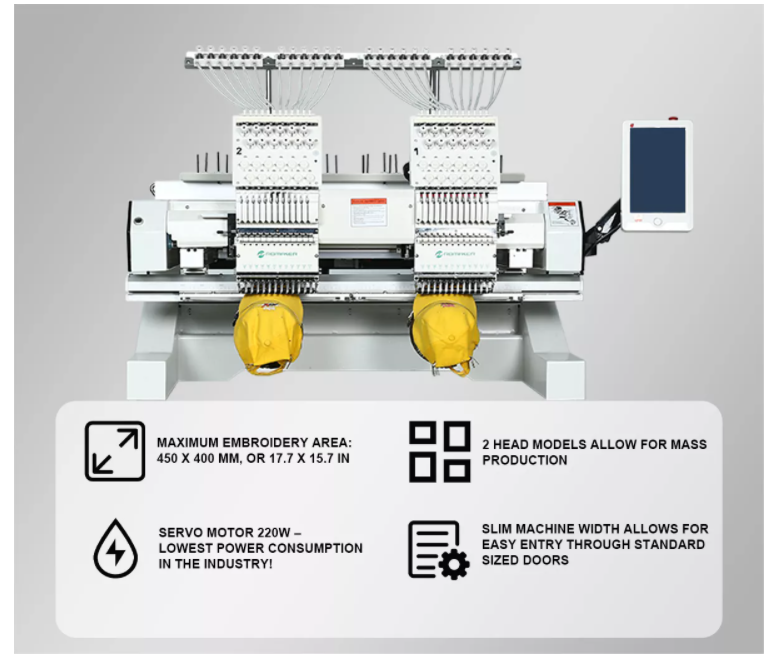

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy