9 月 . 01, 2024 01:16 Back to list

High-Quality 3 Head Embroidery Machines | Reliable Manufacturing Solutions

Understanding the World of 3% Head Embroidery Machine Factories

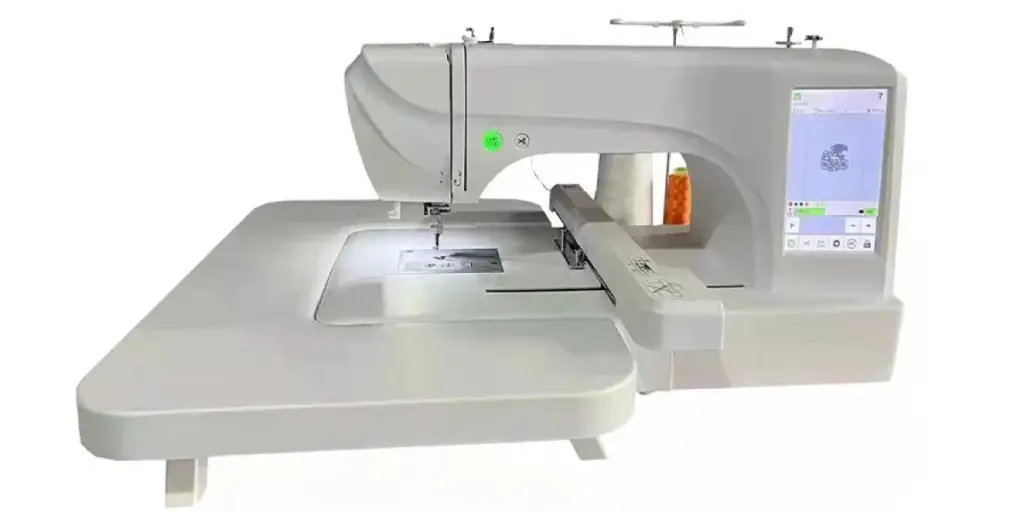

In the ever-evolving landscape of textile manufacturing, the need for precision and efficiency has never been more critical. Among various advanced tools available, embroidery machines stand out for their ability to create intricate designs on fabric. One particular category that has gained attention is the 3% head embroidery machine. This type of machine is known for its unique operational capabilities and the efficiency it brings to the embroidery process.

What is a 3% Head Embroidery Machine?

A 3% head embroidery machine refers to a specialized machine that can operate with multiple heads—specifically three. These machines are designed to enhance productivity while maintaining the quality of the embroidery. The term 3% doesn’t literally mean three heads; rather, it implies that the machines optimize multi-head capabilities, which allows for the simultaneous stitching of multiple designs or the repetition of the same design across several items. This attribute is particularly beneficial for factories looking to maximize output while minimizing operational costs.

The Benefits of Using 3% Head Machines in Factories

1. Increased Productivity One of the primary advantages of a 3% head embroidery machine is the significant boost in productivity it offers. By allowing several heads to operate simultaneously, factories can fulfill orders faster without compromising quality.

2. Cost Efficiency With the ability to produce more items in less time, factories can effectively reduce labor costs and increase their overall profit margins. This is crucial for businesses looking to stay competitive in a fast-paced market.

3 head embroidery machine factories

3. Consistent Quality Multi-head machines maintain uniform tension and fabric handling, ensuring that each design is embroidered to the highest standard. This consistency is vital for businesses that pride themselves on their craftsmanship, as it helps in building a strong reputation among customers.

4. Enhanced Flexibility These machines can accommodate a wide range of fabrics and designs, making them ideal for various industries—from fashion to promotional merchandise. Factories can easily switch between different projects without needing extensive reconfiguration, allowing for better flexibility in production scheduling.

The Role of Factories in the Supply Chain

3% head embroidery machine factories play a crucial role in the global supply chain of textiles. As demand for custom embroidered products continues to rise, these factories need to adopt advanced technologies to keep pace. Moreover, sustainability has also become a key concern, prompting manufacturers to invest in energy-efficient machines and practices that reduce waste.

Future Trends in Embroidery Machine Manufacturing

As technology advances, we can expect to see further innovations in embroidery machine manufacturing. The integration of automation and artificial intelligence is likely to enhance the functionality of 3% head machines. Features such as real-time monitoring, predictive maintenance, and enhanced design software will provide factories with greater control over production processes.

In conclusion, 3% head embroidery machine factories represent the future of textile manufacturing. By leveraging the benefits of multi-head technology, these factories can optimize their operations, ensure unparalleled quality, and meet the increasing demands of a dynamic market. As we look ahead, it will be fascinating to see how these factories evolve and adapt to new challenges, ultimately shaping the world of embroidery in profound ways.

-

Professional Embroidery Machines High-Speed Industrial Solutions & Custom Designs

NewsMay.30,2025

-

Premium 2-Head Embroidery Machines Reliable Manufacturers & Suppliers

NewsMay.30,2025

-

12 Head Embroidery Machines High-Speed & Precision Stitching

NewsMay.30,2025

-

Premium Tshirt Embroidery Machines High-Speed & Precision Stitching

NewsMay.29,2025

-

6 Head Embroidery Machines High-Speed Multi-Head Designs & Suppliers

NewsMay.29,2025

-

Commercial Automatic 2 Heads Embroidery Machine Caps and shirts 12 15 Needles Two Heads Computerized Embroidery Machine

NewsMar.07,2025

Copyright © 2025 Xingtai Pufa Trading Co., Ltd All Rights Reserved. Sitemap | Privacy Policy